uniaxial powder tester

Assess and Rank Powder Flowability

The Uniaxial Powder Tester (UPT) is a stand-alone uniaxial shear tester for simple, sensitive and cost effective powder characterisation. The instrument delivers repeatable and reliable measurements, providing a robust alternative to traditional powder testing techniques.

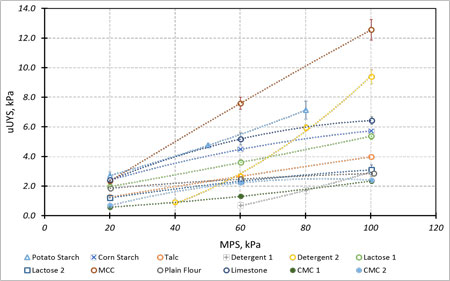

Uniaxial testing first involves the construction of a consolidated powder column. This is then removed from its confining sleeve before being fractured through the application of a vertical stress, directly measuring the uniaxial Unconfined Yield Strength (uUYS). This technique can therefore be used to assess and rank powder flowability.

Cohesive powders have relatively strong inter-particular forces, which encourage the particles to bond together rather than moving easily relative to one another. By contrast, in non-cohesive powders, the tensile forces between particles tend to be much weaker.

Uniaxial powder testing is a direct and reliable method for measuring the uUYS and Flow Function of powders.

Benefits of the Uniaxial Powder Tester

- Direct uUYS (σc) and Flow Function (FF) measurements

- Fast

- Repeatable

- Low Cost

- Versatile

- Easy to use

- Intuitive, easy to interpret results

- Robust

- Bespoke software

The uniaxial Unconfined Yield Strength (uUYS) is a measurement of stress required to break or fail a previously consolidated, unconfined column of powder. The uUYS is similar to the Unconfined Yield Strength (UYS), a parameter derived from rotational shear testers. However, it should be noted that due to the different consolidation and failure protocols of uniaxial and rotational testers, it does not always follow that values for uUYS are identical to values of UYS.

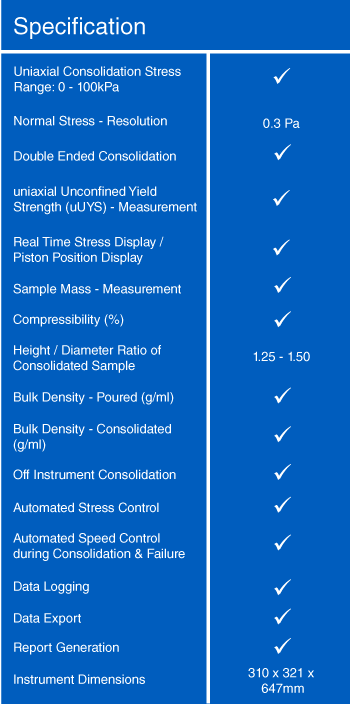

Features of the Uniaxial Powder Tester

The UPT's level of automation and low operator input means the instrument delivers highly repeatable data.

Off-Instrument Consolidation

The innovative offline Consolidation Station provides users with additional testing capabilities. It allows powder samples to be subjected to a range of environmental conditions, separately from the main instrument, such as elevated temperature and humidity for extended periods under the desired MPS. This allows for the simulation of many industrial processes without occupying instruments for long periods of time.

The Consolidation Station can provide up to 100 kPa of applied stress and can be placed in an oven at temperatures up to 70°C.

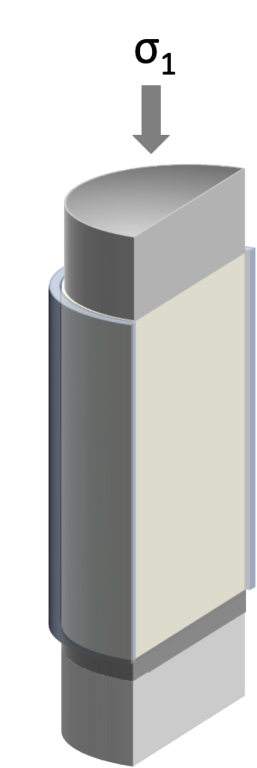

Principles of Uniaxial Testing

Sample is loaded into a cylinder and consolidated with a Major Principal Stress (σ1) to form a powder column

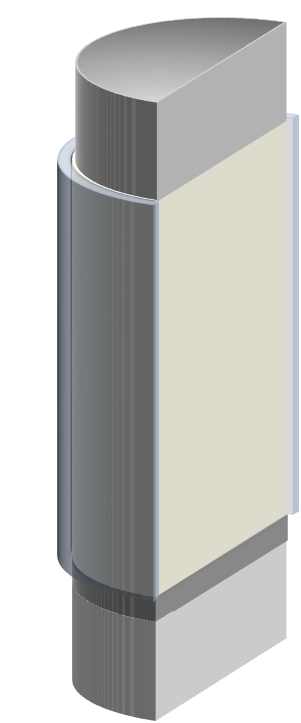

Major Principal Stress and cylinder are removed to leave a free-standing consolidated powder column

Column is fractured through the application of a compressive stress, and derive uniaxial Unconfined Yield Strength